ABOUT US

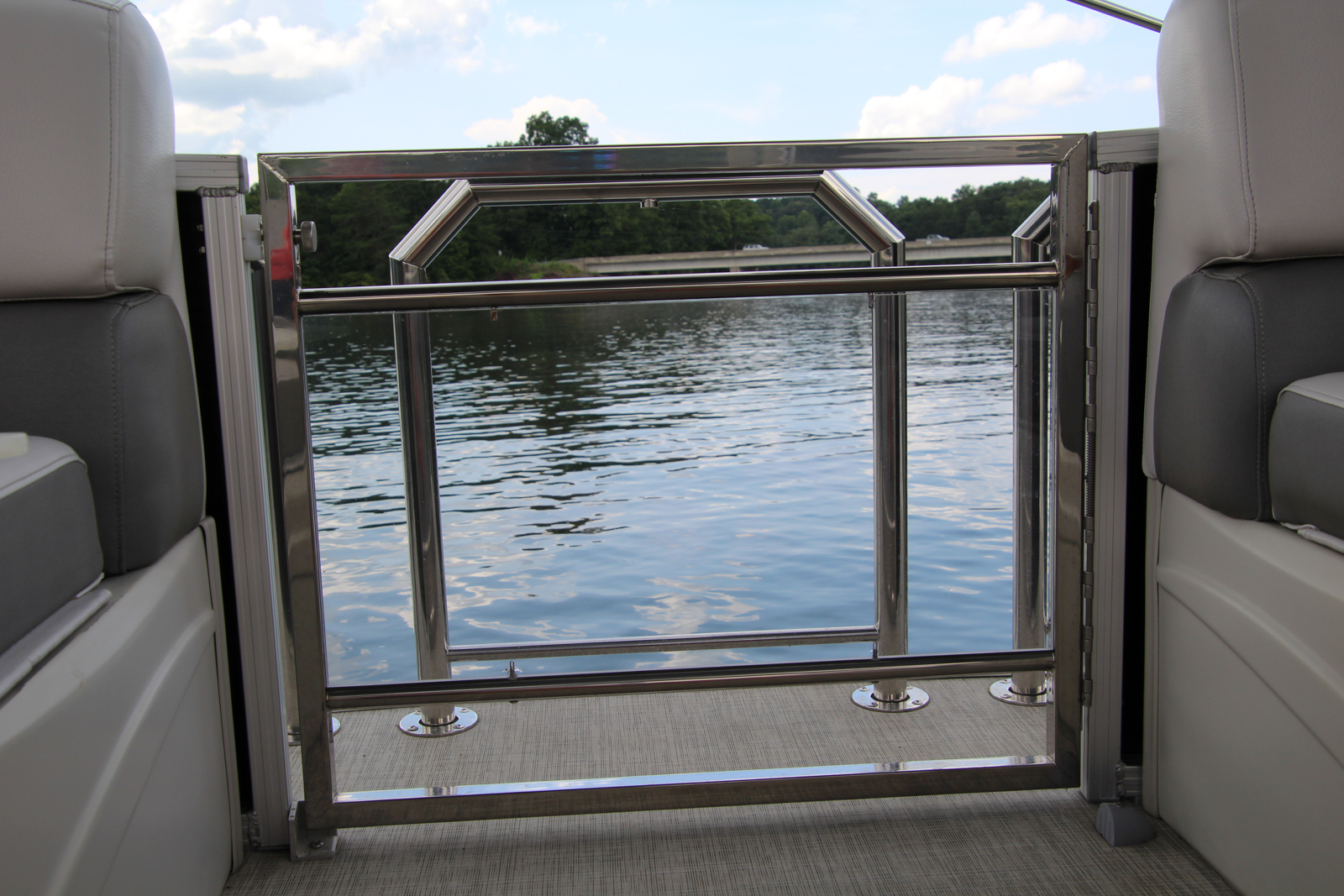

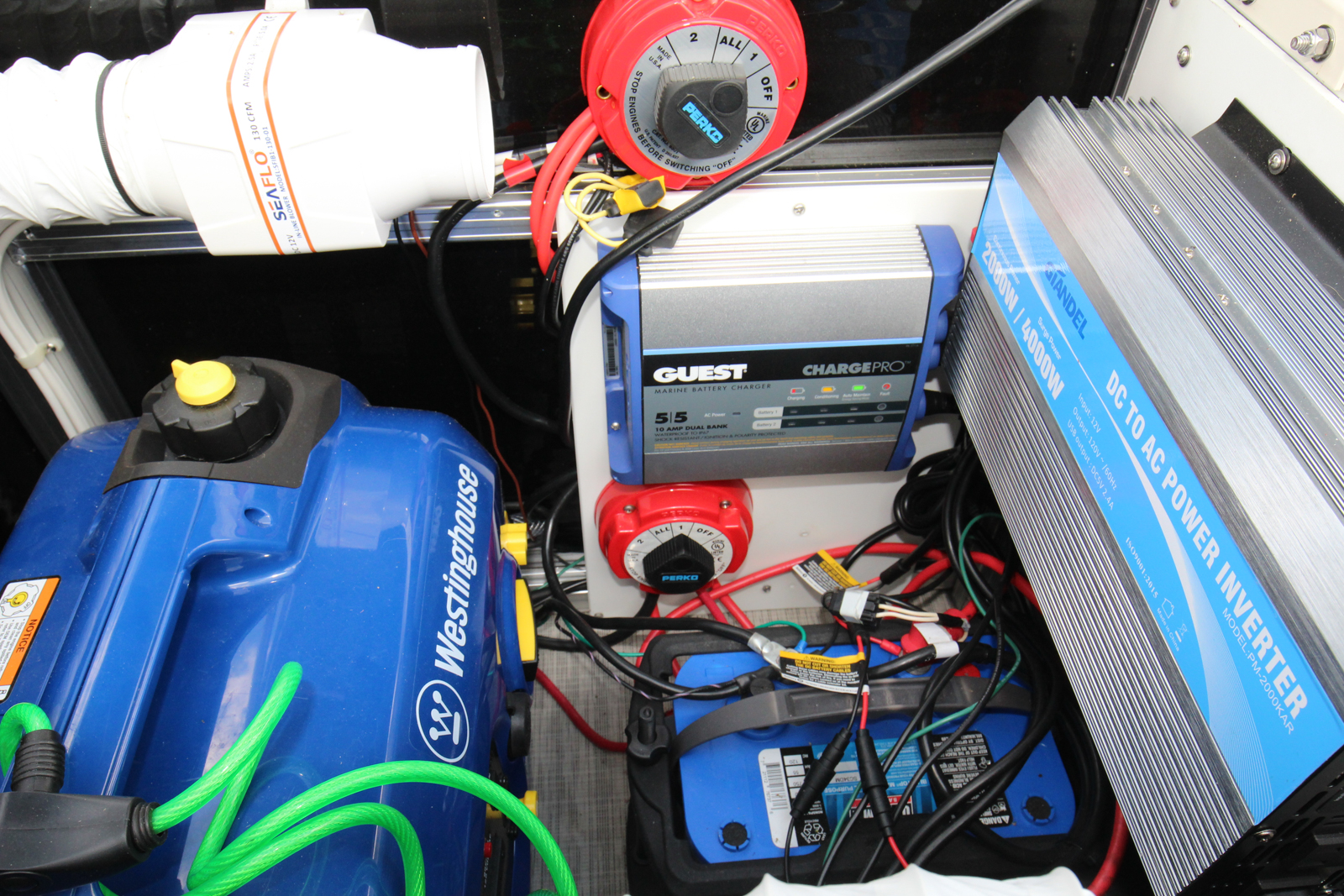

In 1968 Captain Joe Zsido, President, CEO, and Founder of Custom Stainless Steel, Inc. began his career with stainless steel fabrication in New Jersey. Today Custom Stainless Steel services different boat manufacturers and their dealers across the country from its headquarters in Benton, Illinois. Under that roof, Captain Joe Zsido gathered several patents as he creatively solved the stainless needs of his customers. CSS has and will fabricate anything made of stainless or aluminum from bow rails to door latches, telescoping ski pylons, T tops and Sport Arches.

With over 50 years experience and staffed by several individuals ranging from 10 to 30 years of experience each in the Marine Stainless and Aluminum Fabrication Industries. Today CSS offers a complete line of products to some of the highest quality boat builders. Of these companies, Cobalt, Crownline, Formula, and Nautique by Correct Craft have been rated by J.B. Powers consumer reports to be some of the highest quality boats built in the industry.

Products built by CSS are made of the most durable and highest quality materials available, for Boats 14 foot to Yachts 140 feet in length. Using marine grade Aluminum and type 304L and 316L Stainless Steel. CSS quality is second to none. Backed by a LIMITED WARRANTY to offer the best possible service and quality available.

-

DEVELOPMENT

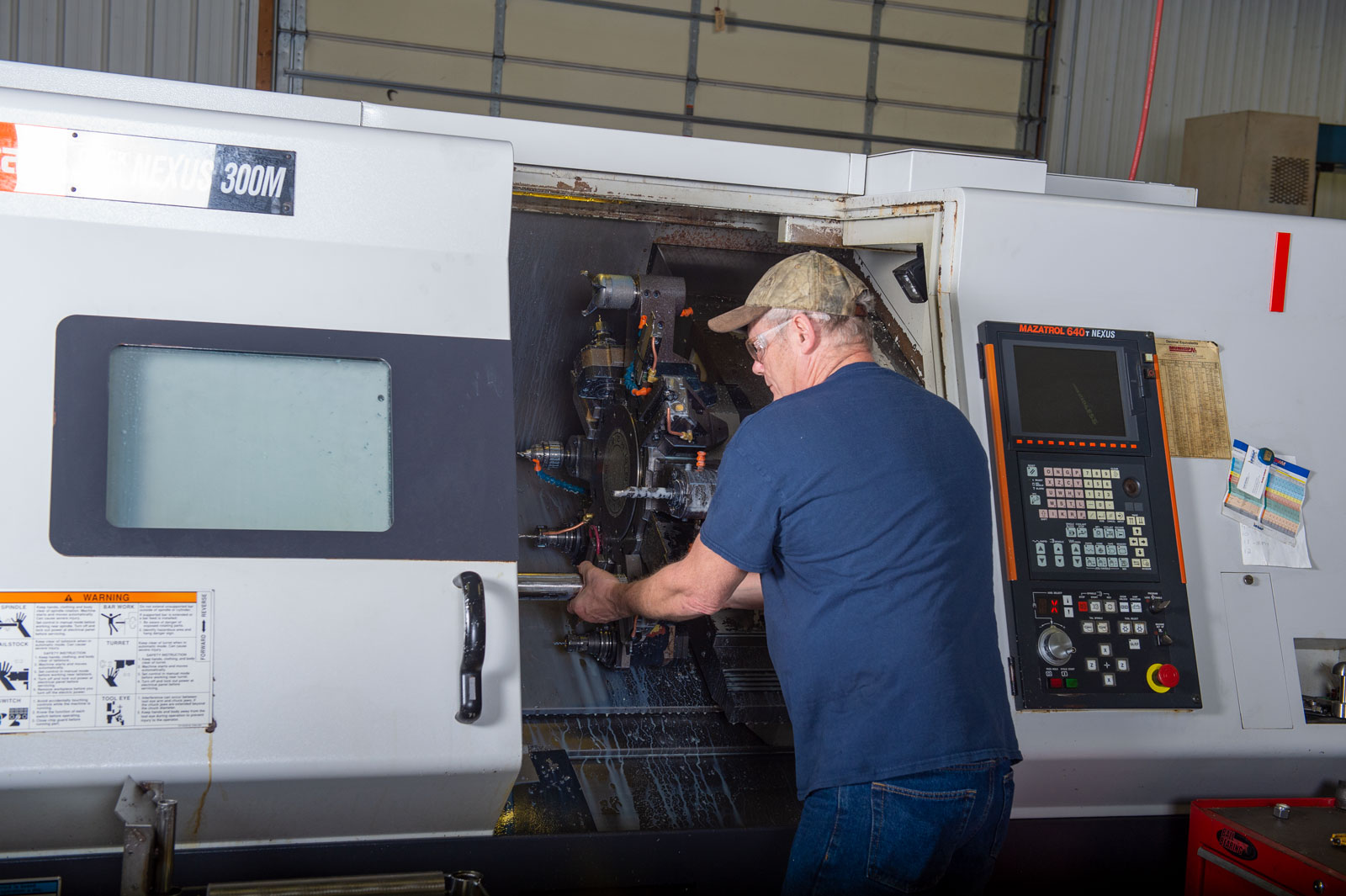

A professional approach with our experienced staff and cutting-edge technology to create a seamless path to the final product. Following the approval of each prototype, fixtures and jigs along with detailed build instructions and drawings are created.

-

DESIGN

We review the concept with our customer's engineering design teams to bring their visions to reality. Our unique fabricating process with today's technology and equipment, we provide our customers the quality products they have grown to expect from Custom Stainless Steel!

-

PRODUCTION

We can now produce the developed product in quantities. Now the part can be fabricated in fixtures to ensure consistency. Also, each piece goes through a final inspection to be approved. The Q&A process includes fitting in or on dedicated fixtures. This now guarantees a quality product.